Welcome to our new site, if you can’t find what you’re looking for please get in touch via our contact us page.

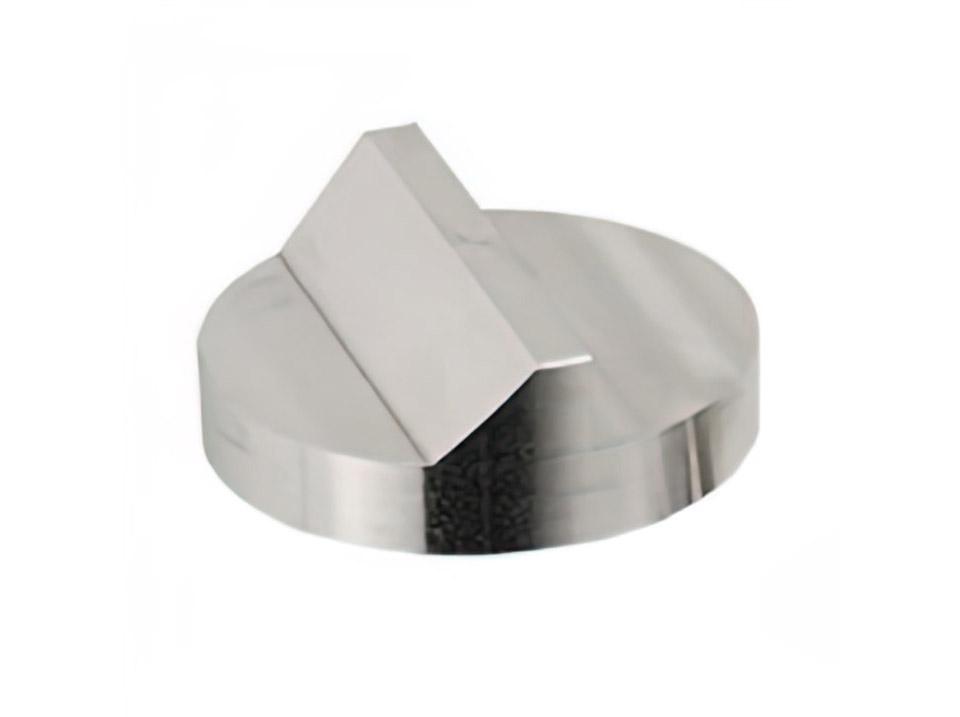

JEOL Ø32 x 12mm angled SEM stub with 45 and 90 degree

JEOL Ø32 x 12mm angled SEM sample stub with 45 and 90 degree – aluminium (pkg/5)

£32.41

Related products

-

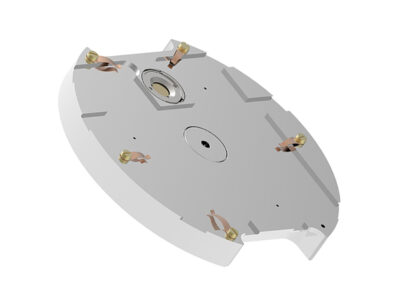

ST-010 object slide table

ST-010 specimen stage for microscopy slides. Comprises base plate connected to the tilt and height adjustable specimen table of the CCU-010 base unit. For two microscopy slides 76 x 26mm or one slide 76 x 52mm. Can also be used for coverslips. Twelve M2 threaded holes for S-clips. Two FTM quartz crystal positions (centre and edge). Six mounting clips M2 included.

SKU: 1000088Price On Request £0.00 Add to basketAdd to QuoteWithin your QuoteAdd to QuoteST-010 object slide table

ST-010 specimen stage for microscopy slides. Comprises base plate connected to the tilt and height adjustable specimen table of the CCU-010 base unit. For two microscopy slides 76 x 26mm or one slide 76 x 52mm. Can also be used for coverslips. Twelve M2 threaded holes for S-clips. Two FTM quartz crystal positions (centre and edge). Six mounting clips M2 included.

£0.00Price On Request -

Indium Tin Oxide target (ITO), Ø54 x 2mm (90/10- 99.99%)

Indium tin oxide (ITO) sputter coater target – 90/10 Ø 54 x 2mm, high purity 99.99%

SKU: 300012Price On Request £0.00 Add to basketAdd to QuoteWithin your QuoteAdd to QuoteIndium Tin Oxide target (ITO), Ø54 x 2mm (90/10- 99.99%)

Indium tin oxide (ITO) sputter coater target – 90/10 Ø 54 x 2mm, high purity 99.99%

£0.00Price On Request -

Edwards nXDS10i dry scroll pump

Edwards nXDS10i dry scroll pump.Peak pumping speed 11.4 m3/hr (6.7 cfm). Ultimate pressure 0.007 mbar (0.005 torr).Pump controller with push button control- remote serial and parallel control plus USB service interface.Supply 100-127/200-240V (+/- 10%) 1ph 50/60Hz without user intervention.Inlet port : NW25- exhaust port : NW25

SKU: A73601983Price On Request £0.00 Add to basketAdd to QuoteWithin your QuoteAdd to QuoteEdwards nXDS10i dry scroll pump

Edwards nXDS10i dry scroll pump.Peak pumping speed 11.4 m3/hr (6.7 cfm). Ultimate pressure 0.007 mbar (0.005 torr).Pump controller with push button control- remote serial and parallel control plus USB service interface.Supply 100-127/200-240V (+/- 10%) 1ph 50/60Hz without user intervention.Inlet port : NW25- exhaust port : NW25

£0.00Price On Request -

CCU-010 LV (standard vacuum)

Safematic CCU-010 LV compact, fully automatic standard vacuum coating system. Including dual-position terminating film thickness monitoring system. Please note that for a complete working system the CCU-010LV requires the following: backing rotary vacuum pump (A65201903), oil mist filter (A46226000) and pumping hose (C10514297). Select coating head option SP-010 (sputteringing), CT-010 (carbon evaporation) or both. Select required sputtering target(s). Detailed description: • glass work chamber- 104 mm Ø x 106 mm (DN 100 ISO-KF compatible)• implosion guard and safety monitoring• table (Ø 80 mm) – tilt and height adjustable • multi-sample holder for 20 standard (13 mm) pin stubs to meet most requirements• film thickness monitor (FTM) based on a quartz crystal oscillator- usable in two positions (centre/edge)• full range power supply (90-260VAC- 50/60Hz)• coating process head interface (gas and electric) including automatic detection• 5.7“ TFT touch display• recipe-driven user interface for guaranteed reproducible results• storage / view of the last ten coating processes• automatic vent of the system when power failures – prevents backstreaming of oil from the rotary pump• intuitive operator’s software• graphic display of process data with Windows-based software Coating LAB (option)• flange connection (KF25) for connection of an external roughing pump• external alarm connector• USB service interface for easy analysis and software upgrades• automatic valve control for two process gases and venting• operating manual

SKU: 100000Price On Request £0.00 Add to basketAdd to QuoteWithin your QuoteAdd to QuoteCCU-010 LV (standard vacuum)

Safematic CCU-010 LV compact, fully automatic standard vacuum coating system. Including dual-position terminating film thickness monitoring system. Please note that for a complete working system the CCU-010LV requires the following: backing rotary vacuum pump (A65201903), oil mist filter (A46226000) and pumping hose (C10514297). Select coating head option SP-010 (sputteringing), CT-010 (carbon evaporation) or both. Select required sputtering target(s). Detailed description: • glass work chamber- 104 mm Ø x 106 mm (DN 100 ISO-KF compatible)• implosion guard and safety monitoring• table (Ø 80 mm) – tilt and height adjustable • multi-sample holder for 20 standard (13 mm) pin stubs to meet most requirements• film thickness monitor (FTM) based on a quartz crystal oscillator- usable in two positions (centre/edge)• full range power supply (90-260VAC- 50/60Hz)• coating process head interface (gas and electric) including automatic detection• 5.7“ TFT touch display• recipe-driven user interface for guaranteed reproducible results• storage / view of the last ten coating processes• automatic vent of the system when power failures – prevents backstreaming of oil from the rotary pump• intuitive operator’s software• graphic display of process data with Windows-based software Coating LAB (option)• flange connection (KF25) for connection of an external roughing pump• external alarm connector• USB service interface for easy analysis and software upgrades• automatic valve control for two process gases and venting• operating manual

£0.00Price On Request