PIE Scientific TEM rod store

TEM specimen rod storage system from PIE Scientific is a compact unit that enables storage of up to six TEM specimen rods under vacuum. Six storage cells can be individually configured to support specimen rods from FEI/ThermoFisher, JEOL or Hitachi. For larger EM laboratories the system can be extended by chain linking multiple units.

The TEM sample rod storage system can share the same pump as a Tergeo-EM plasma cleaner and can be pumped with a separate turbo or dry scroll pump station. For details see: vacuum pumps.

- Fully automated

- Storage cells can be individually pumped and vented with electronic solenoid valves

- LED indicates the cell is under the vacuum, light off vented

- Minimal metal tubing to minimize outgassing, and reduce contamination

- Multiple storage stations can be chained linked to share a same vacuum pump

- Metal tubes under vacuum – minimal outgassing

- Pumped by an external turbo pump station or by an dry scroll pump

- Easy to operate, easy to maintain and service

- The storage station can also share the oil-free dry scroll vacuum pump with the Tergeo-EM plasma cleaner

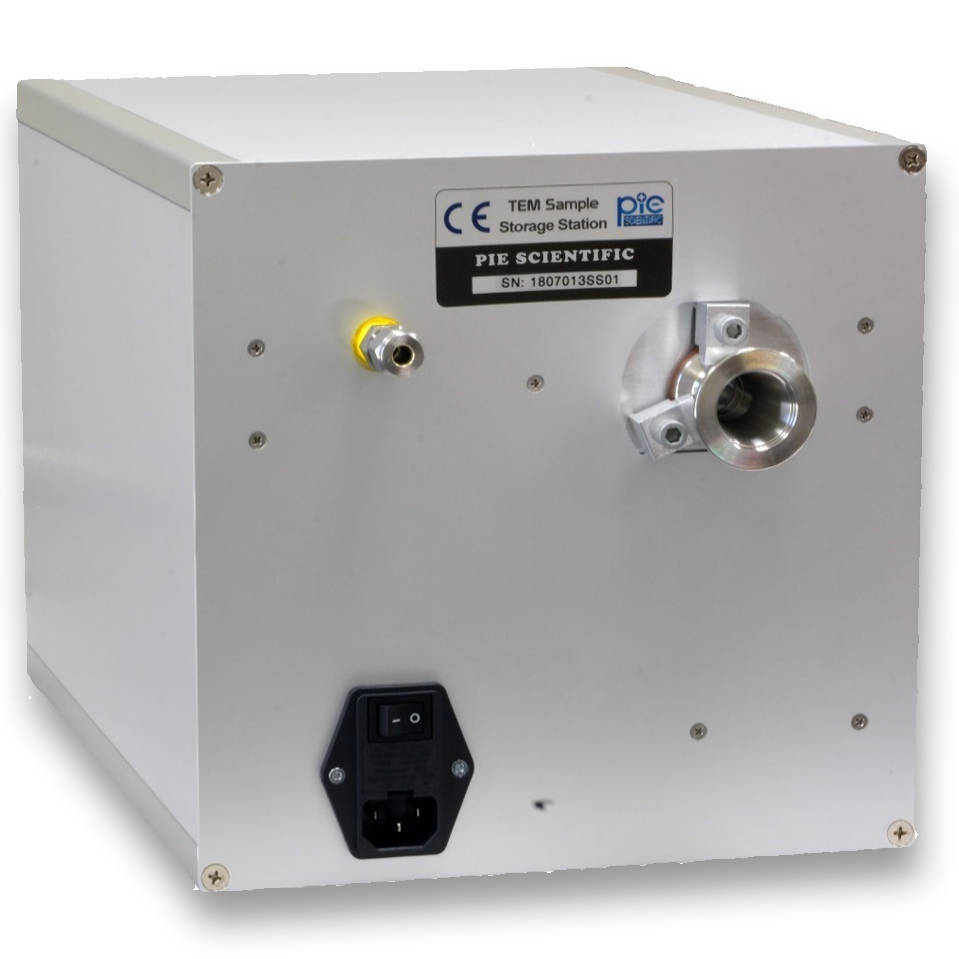

Vacuum and gas connections

On the back there is a port for introducing a venting gas (pure argon, nitrogen etc) and a NW25 or NW40 pumping port for connecting to either a turbo pumping station or dry scroll pump. For details see: vacuum pumps.

The TEM specimen rods storage system requires a suitable vacuum pump.

Our recommendation is the Edwards nXDS6i dry scroll vacuum pump (A73501983). For details see: vacuum pumps.

Dimensions:

240mm(W) X 240mm (H) X 368mm (D), distance between storage cells: 80mm

PIE Scientific specialise in developing advanced plasma systems for plasma etching, cleaning, surface treatment, ion and electron beam production applications. The company was founded by alumni of the Plasma and Ion Source Technology group in the Lawrence Berkeley National Laboratory. After 15 years of experience in developing advanced semiconductor capital equipment in Silicon Valley, they realized that many existing low-cost plasma cleaners and plasma treatment systems were still using decades-old technology. Therefore, they decided to bring state-of-the-art plasma technology developed for the semiconductor industry and nuclear research into affordable plasma instruments. Their SmartClean™ technology has been well-received by customers.

Ordering information:

-

TEM sample rod storage system

TEM sample storage system. Each storage cells can be individually pumped or vented using electronic solenoid valves. There is a total six storage cells per unit which can be individually configured to support FEI/ThermoFisher, JEOL or Hitachi sample rods. The storage system can be chain linked to multiple units. The system can share the same pump as the Tergeo-EM plasma cleaner or can be pumped with a separate turbo or dry scroll pump station. All metal tubes are maintained under vacuum for minimal outgassing.

Price On Request £0.00 Add to basketTEM sample rod storage system

TEM sample storage system. Each storage cells can be individually pumped or vented using electronic solenoid valves. There is a total six storage cells per unit which can be individually configured to support FEI/ThermoFisher, JEOL or Hitachi sample rods. The storage system can be chain linked to multiple units. The system can share the same pump as the Tergeo-EM plasma cleaner or can be pumped with a separate turbo or dry scroll pump station. All metal tubes are maintained under vacuum for minimal outgassing.

£0.00Price On Request