Faraday cup

Micro to Nano EM-Tec B100 Faraday cup has been designed to enable precise beam current measurements on SEM, FESEM, FIB, EPMA or Microprobe systems. Precise beam current measurements are useful for quantitative X-ray analysis and for consistent and reproducible X-ray mappings and line scans.

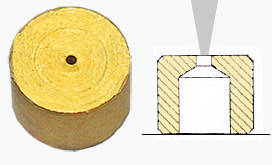

EM-Tec B100 features a 100µm diameter hole with a wider cavity inside. This Faraday cup needs to be mounted on a specimen stub or specimen holder with carbon conductive cement and uses the existing grounding path on the specimen stage for measuring absorbed current. The small aperture opening of 100µm and the larger cavity behind the aperture prevent backscatter electrons from escaping. All primary, backscatter and virtually all secondary electrons are absorbed in the EM-Tec B100 Faraday cup. The result is an absorption efficiency of 99% or better for electrons and ions in the 2-30kV range.

To use the EM-Tec B100 Faraday cup select point mode on your system and direct the beam into the middle of the hole of the Faraday cup. If the instrument you are using does not include an absorbed current meter, a separate Pico-ammeter needs to be connected.

|

Product code |

#36-000800 |

|

Material |

Brass |

|

Outside diameter |

2.5mm |

|

Height |

2mm |

|

Hole size |

Ø100µm |

|

Cavity size |

Ø1.4 x 1.5mm |

Introduction

Precise beam current measurements are needed to check the stability of the electron or ion beam over longer periods of time or to adjust to a specific beam current. This might be needed for:

- quantitative X-ray micro-analysis when using references standards

- uniform and reproducible X-ray mappings and line scan

- electron beam lithography

- comparative measurements

- adjusting ion beam milling rates.

Measuring the beam current at the point where the beam hits the sample surface gives the most accurate results. A Faraday cup is a useful tool for precise measurements of the electron or ion beam. It consists of an enclosed cavity with a small opening through which the beam can be directed.

Sometimes beam measurements are made on graphite (carbon) or an electron beam aperture glued with carbon cement is used. Both methods are less precise:

- measuring beam current on carbon will not account for backscattered and secondary electrons

- an aperture glued with carbon cement lacks a larger cavity; it is only precise when a larger cavity has been constructed underneath the aperture.

EM-Tec B100 Faraday cup construction

The EM-Tec B100 consists of single piece of brass with outside dimensions of Ø2.5 x 2mm. The top of the Faraday cup includes a Ø100µm hole. Behind this 100µm aperture, there is a larger cavity of approximately Ø1.4 x 1.5mm.

When used, the EM-Tec B100 Faraday cup must be mounted on a sample stub or sample holder with conductive carbon cement and the small Ø100µm aperture facing the pole piece of the SEM.

When the electron or ion beam is directed into the middle of the small aperture; all primary, backscattered and virtually all secondary electrons are absorbed by the Faraday cup and hence the beam current can be determined. When properly used, the EM-Tec B100 Faraday cup efficiency is >99% in the 2-30kV range.

Directions for using the EM-Tec B100 Faraday cup

When using the EM-Tec B100 Faraday cup on your SEM, FESEM, FIB or Microprobe system, the holder with the Faraday cup must be electrically connected to the sample stage. Select point mode on your system and make sure that the beam is directed in the middle of the aperture of the Faraday cup. If your system includes an absorbed current meter you can use this meter to measure the beam current.

If your system does not include an absorbed current meter, you have to connect a pico-ammeter (range 10-3 to 10-12 A) using a ground connection on the outside of the SEM chamber. Most SEMs provide such a connection on the outside of the SEM chamber or on the SEM chamber door. This is most likely a BNC connector capped with a metal cap to ensure proper grounding. Removal of the metal cap and connecting the pico-ammeter enables measuring the beam current. The power to the pico-ammeter needs to be provided by the same electrical circuit as the SEM. When removing the pico-ammeter, re-install the metal cap on the connector.

If the grounding cable from the SEM sample stage is connected to the inside of the SEM chamber, please consult the manufacturer or your service engineer if they can provide an absorbed current feedthrough.

With the measurement circuit installed, mount the EM-Tec B100 Faraday cup on the SEM sample stage and position the Faraday cup under the beam. Use point mode (or very high magnification scanning mode) to direct the beam into the middle of the aperture of the Faraday cup. Adjust condenser settings to change or require the desired beam current, note the beam current.

Maintenance, handling and cleaning

Store the EM-Tec B100 Faraday cage in a dust free and clean environment. Remove dust for use with a blower or duster.

Handle the EM-Tec B100 Faraday cup with plastic tweezers or plastic tipped tweezers to avoid damage of the relatively soft brass.

When used under normal conditions there is no maintenance or cleaning needed. If the aperture opening gets contaminated or charging occurs, the aperture opening needs to be cleaned:

- either use a plasma cleaner to remove carbon deposits

- or use mechanical cleaning with Wenol metal polish (#53-000100) or diamond polishing paste (29-001599) and wooden picks (#52-005023). Sonicate afterward in a 50/50 solution of isopropanol/acetone and let dry. If solvents are used, remounting with conductive carbon cement will be necessary

Ordering information:

-

EM-Tec B100 Faraday cup with 100µm hole

EM-Tec B100 Faraday cup with 100µm hole (each)

£85.52 Add to basketEM-Tec B100 Faraday cup with 100µm hole

EM-Tec B100 Faraday cup with 100µm hole (each)

£85.52