Welcome to our new site, if you can’t find what you’re looking for please get in touch via our contact us page.

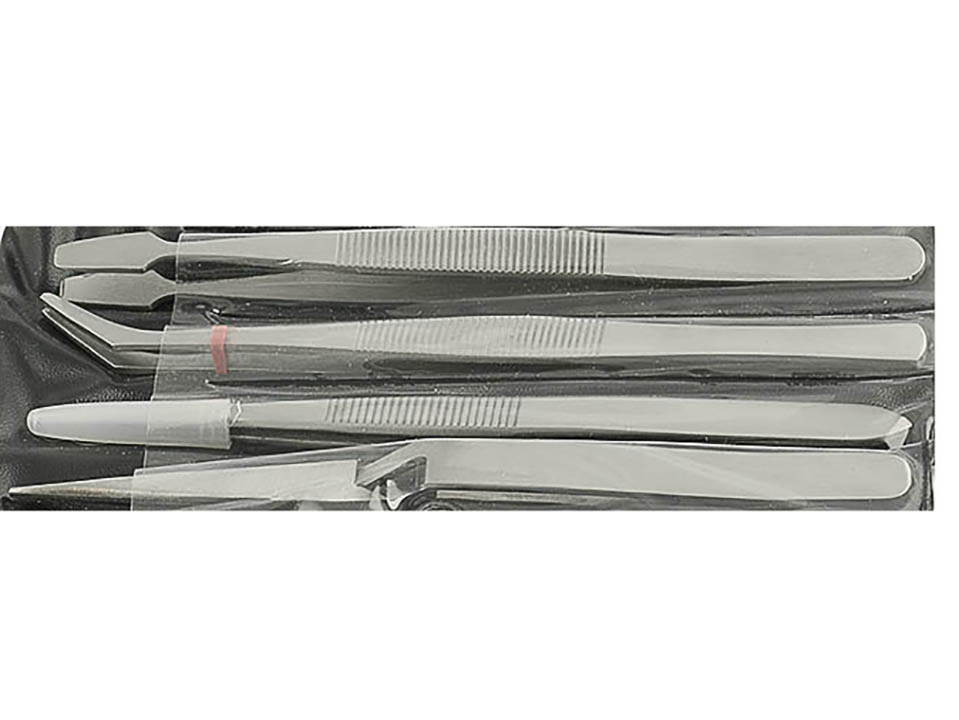

Set of four short strong tweezers includes 110, 127, 126, 130X

Value-Tec set of four short industrial strong tweezers includes styles 110, 127, 126 and 130X – magnetic stainless steel (set/4)

£6.75

Related products

-

305.MS 12inch steam forceps with PVC covered tips – 305mm

Value-Tec 305MS 12inch steam forceps with PVC covered tips, 305mm – magnetic stainless steel (each)

SKU: 50-014330£5.85 Add to basketAdd to QuoteWithin your QuoteAdd to Quote305.MS 12inch steam forceps with PVC covered tips – 305mm

Value-Tec 305MS 12inch steam forceps with PVC covered tips, 305mm – magnetic stainless steel (each)

£5.85 -

Strong tweezers style 610 with straight serrated pointed tips

Value-Tec 610MS industrial strong tweezers- style 610- straight serrated pointed tips- 150mm- magnetic stainless steel (each)

SKU: 50-014361£2.66 Add to basketAdd to QuoteWithin your QuoteAdd to QuoteStrong tweezers style 610 with straight serrated pointed tips

Value-Tec 610MS industrial strong tweezers- style 610- straight serrated pointed tips- 150mm- magnetic stainless steel (each)

£2.66 -

Strong tweezers style 110 with straight serrated pointed tips

Value-Tec 110MS industrial strong tweezers, style 110, straight serrated pointed tips, 115mm – magnetic stainless steel (each)

SKU: 50-014310£2.25 Add to basketAdd to QuoteWithin your QuoteAdd to QuoteStrong tweezers style 110 with straight serrated pointed tips

Value-Tec 110MS industrial strong tweezers, style 110, straight serrated pointed tips, 115mm – magnetic stainless steel (each)

£2.25 -

CCU-010 LV (standard vacuum)

Safematic CCU-010 LV compact, fully automatic standard vacuum coating system. Including dual-position terminating film thickness monitoring system. Please note that for a complete working system the CCU-010LV requires the following: backing rotary vacuum pump (A65201903), oil mist filter (A46226000) and pumping hose (C10514297). Select coating head option SP-010 (sputteringing), CT-010 (carbon evaporation) or both. Select required sputtering target(s). Detailed description: • glass work chamber- 104 mm Ø x 106 mm (DN 100 ISO-KF compatible)• implosion guard and safety monitoring• table (Ø 80 mm) – tilt and height adjustable • multi-sample holder for 20 standard (13 mm) pin stubs to meet most requirements• film thickness monitor (FTM) based on a quartz crystal oscillator- usable in two positions (centre/edge)• full range power supply (90-260VAC- 50/60Hz)• coating process head interface (gas and electric) including automatic detection• 5.7“ TFT touch display• recipe-driven user interface for guaranteed reproducible results• storage / view of the last ten coating processes• automatic vent of the system when power failures – prevents backstreaming of oil from the rotary pump• intuitive operator’s software• graphic display of process data with Windows-based software Coating LAB (option)• flange connection (KF25) for connection of an external roughing pump• external alarm connector• USB service interface for easy analysis and software upgrades• automatic valve control for two process gases and venting• operating manual

SKU: 100000Price On Request £0.00 Add to basketAdd to QuoteWithin your QuoteAdd to QuoteCCU-010 LV (standard vacuum)

Safematic CCU-010 LV compact, fully automatic standard vacuum coating system. Including dual-position terminating film thickness monitoring system. Please note that for a complete working system the CCU-010LV requires the following: backing rotary vacuum pump (A65201903), oil mist filter (A46226000) and pumping hose (C10514297). Select coating head option SP-010 (sputteringing), CT-010 (carbon evaporation) or both. Select required sputtering target(s). Detailed description: • glass work chamber- 104 mm Ø x 106 mm (DN 100 ISO-KF compatible)• implosion guard and safety monitoring• table (Ø 80 mm) – tilt and height adjustable • multi-sample holder for 20 standard (13 mm) pin stubs to meet most requirements• film thickness monitor (FTM) based on a quartz crystal oscillator- usable in two positions (centre/edge)• full range power supply (90-260VAC- 50/60Hz)• coating process head interface (gas and electric) including automatic detection• 5.7“ TFT touch display• recipe-driven user interface for guaranteed reproducible results• storage / view of the last ten coating processes• automatic vent of the system when power failures – prevents backstreaming of oil from the rotary pump• intuitive operator’s software• graphic display of process data with Windows-based software Coating LAB (option)• flange connection (KF25) for connection of an external roughing pump• external alarm connector• USB service interface for easy analysis and software upgrades• automatic valve control for two process gases and venting• operating manual

£0.00Price On Request