RMC glass knifemaker

High quality ultra-thin sections requires high quality glass knives.

Glass knives produced by the ‘balanced break’ method are proven to be the sharpest and most consistent compared to traditional glass breaking methods. They have become well established as the preferred alternative to diamond knives used for cryosectioning applications such as the Tokuyasu method.

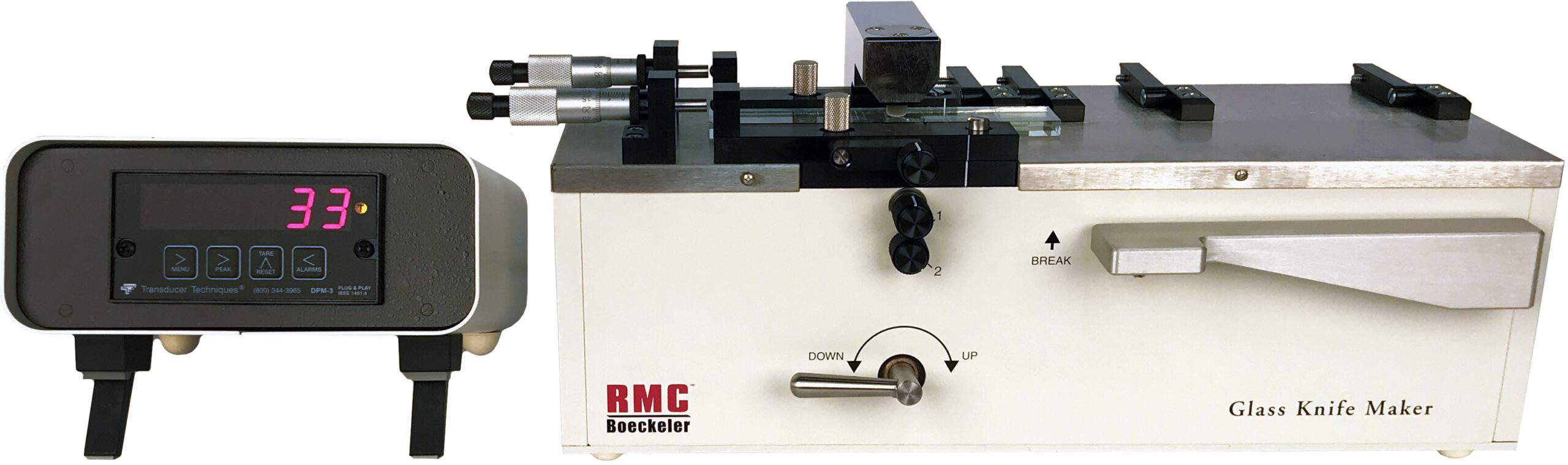

The RMC GKM-2 Glass Knifemaker is specifically designed to incorporate the “balanced break” method to produce optimum knife edges. Balanced breaks require equal lengths of glass on each side of the score, along with a mechanism that applies equal load to each side, resulting in a slow, controlled and straight break.

To achieve consistent, controlled breaks, two aspects of the breaking process must be measurably controlled: position and load. The RMC GKM-2 glass knifemaker accurately positions the glass using precision micrometers. During the glass breaking process the load exerted is controlled by the clamping handle and breaking arm with constant feedback displayed on the digital readout. This enables the operator to consistently reproduce breaking pressure during the final controlled break for more accurate knives every time.

The rectangular shaped body of the RMC GKM-2 glass knifemaker is machined from solid metal components for long term stability and precision. It is designed to handle glass strips ranging from 6 mm (1/4″) to 8 mm in thickness, with mechanical stops for producing precise 25 mm glass squares with ease. Micrometers provide reproducible alignment of the 25 mm glass squares for precise diagonal breaks. The alignment is secured by a locking mechanism to maintain your desired setting.

- Solid, heavy design

- Easily produces consistent, controlled breaks

- Digital readout displays load applied to glass as breaking arm is moved

- Produces knives up to 10 mm wide

- “Balanced Break” method for the sharpest knives

- Precision micrometer positioners

- Built-in mechanical stops for easy positioning

- Precision mechanism supports “Slow-Break” technique

Digital display

Two micrometers

Protective goggles

Brush

Instruction manual

Replacement scoring wheels and axle

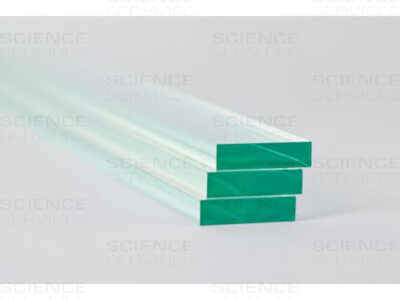

Glass, 1 box 6 mm x 1” x 16” (25.4 x 406 mm) 30 pieces

GKM training video. Detailed instructions on how to make good glass knives with the RMC Glass Knife Maker. 55 minutes in length.

Width: 360mm

Height: 160mm

Depth: 170mm

Weight: 13.6kg

ASY-1035. GKM scoring wheel kit. Includes two (2) replacement scoring wheels and one (1) replacement axle”

GEN-1002. glass strips for GKM2: 6mm x 25.4mm x 406mm, package of 30 pieces

GEN-1003. glass strips for GKM2: 8mm x 25.4mm x 406mm, package of 24 pieces

RMC Boeckeler is a specialist manufacturer of ultramicrotomes, microtomes and related instruments for the TEM and LM markets with a history dating back to 1941.

Based in Tucson Arizona in the USA, RMC Boeckeler is a privately owned. Their instruments are used globally in many fields including materials science and cell biology, with special emphasis in specimen preparation for 3D electron microscopy solutions.

Ordering information:

-

GKM2 Glass Knife Maker

GKM2 : Glass Knife Maker. The pressure sensor and digital display enable the operator to produce accurate knives with each controlled break. Precision micrometers accurately position glass squares for the final break into knives.

Price On Request £0.00 Add to basketGKM2 Glass Knife Maker

GKM2 : Glass Knife Maker. The pressure sensor and digital display enable the operator to produce accurate knives with each controlled break. Precision micrometers accurately position glass squares for the final break into knives.

£0.00Price On Request

-

GKM scoring wheel kit

GKM scoring wheel kitIncludes two (2) replacement scoring wheels and one (1) replacement axle

Price On Request £0.00 Add to basketGKM scoring wheel kit

GKM scoring wheel kitIncludes two (2) replacement scoring wheels and one (1) replacement axle

£0.00Price On Request -

Glass strips for GKM2: 6mm x 25.4mm x 406mm

Glass Strips for GKM2: 6mm x 25.4mm x 406mm- package of 30 pieces

Price On Request £0.00 Add to basketGlass strips for GKM2: 6mm x 25.4mm x 406mm

Glass Strips for GKM2: 6mm x 25.4mm x 406mm- package of 30 pieces

£0.00Price On Request -

Glass strips for GKM2: 8mm x 25.4mm x 406mm

Glass strips for GKM2: 8mm x 25.4mm x 406mm – package of 24 pieces

Price On Request £0.00 Add to basketGlass strips for GKM2: 8mm x 25.4mm x 406mm

Glass strips for GKM2: 8mm x 25.4mm x 406mm – package of 24 pieces

£0.00Price On Request