Welcome to our new site, if you can’t find what you’re looking for please get in touch via our contact us page.

SEM pin stub Ø50mm diameter top, standard pin – aluminium

SEM pin stub Ø50mm diameter top, standard pin – aluminium (pkg/1)

£5.85

Related products

-

Edwards nXDS10i dry scroll pump

Edwards nXDS10i dry scroll pump.Peak pumping speed 11.4 m3/hr (6.7 cfm). Ultimate pressure 0.007 mbar (0.005 torr).Pump controller with push button control- remote serial and parallel control plus USB service interface.Supply 100-127/200-240V (+/- 10%) 1ph 50/60Hz without user intervention.Inlet port : NW25- exhaust port : NW25

SKU: A73601983Price On Request £0.00 Add to basketAdd to QuoteWithin your QuoteAdd to QuoteEdwards nXDS10i dry scroll pump

Edwards nXDS10i dry scroll pump.Peak pumping speed 11.4 m3/hr (6.7 cfm). Ultimate pressure 0.007 mbar (0.005 torr).Pump controller with push button control- remote serial and parallel control plus USB service interface.Supply 100-127/200-240V (+/- 10%) 1ph 50/60Hz without user intervention.Inlet port : NW25- exhaust port : NW25

£0.00Price On Request -

Edwards RV3 rotary vacuum pump (including Ultragrade oil) with 2m UK mains lead

Edwards RV3 Two stage rotary vaccum pump 115/230V- 1-ph- 50/60Hz. Factory set to 230V for Europe• Speed (Pneurop 6602) 50 Hz: 3.3 m3h1 / 2 ft3min1 60Hz: 3.9 m3h1/ 2.3 ft3min1• Ultimate pressure 2.0 x 103mbar / 1.5 x 103 Torr• Inlet flange: NW25 / exhaust flange: NW25• Supplied with: 1 litre of Ultragrade 19 oil-inlet filter and O-ring• EMF10 (A46226000) exhaust oil mist filter recommended • Includes – A50505000UK/Ireland 2m mains lead

SKU: A65201903Price On Request £0.00 Add to basketAdd to QuoteWithin your QuoteAdd to QuoteEdwards RV3 rotary vacuum pump (including Ultragrade oil) with 2m UK mains lead

Edwards RV3 Two stage rotary vaccum pump 115/230V- 1-ph- 50/60Hz. Factory set to 230V for Europe• Speed (Pneurop 6602) 50 Hz: 3.3 m3h1 / 2 ft3min1 60Hz: 3.9 m3h1/ 2.3 ft3min1• Ultimate pressure 2.0 x 103mbar / 1.5 x 103 Torr• Inlet flange: NW25 / exhaust flange: NW25• Supplied with: 1 litre of Ultragrade 19 oil-inlet filter and O-ring• EMF10 (A46226000) exhaust oil mist filter recommended • Includes – A50505000UK/Ireland 2m mains lead

£0.00Price On Request -

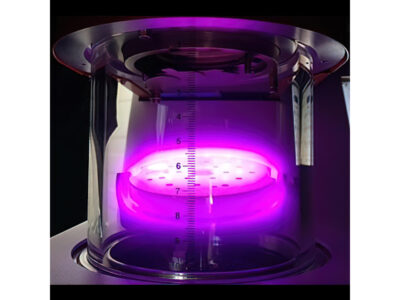

ET-010 integrated plasma stage

Plasma cleaning accessory for the pre-treatment (cleaning) or after-treatment (glow discharge effect) of specimens in combination with a coating process.

SKU: 1000010Price On Request £0.00 Add to basketAdd to QuoteWithin your QuoteAdd to QuoteET-010 integrated plasma stage

Plasma cleaning accessory for the pre-treatment (cleaning) or after-treatment (glow discharge effect) of specimens in combination with a coating process.

£0.00Price On Request -

Rotary support for PS-006

Rotary support for use with the PS-006 planetary gear stage. Includes slip-on specimen holder which converts the planetary gear stage into a rotary stage. Twelve M2 threads for mounting specimens or for the using S-clips. Six mounting clips M2 included.

SKU: 1000089Price On Request £0.00 Add to basketAdd to QuoteWithin your QuoteAdd to QuoteRotary support for PS-006

Rotary support for use with the PS-006 planetary gear stage. Includes slip-on specimen holder which converts the planetary gear stage into a rotary stage. Twelve M2 threads for mounting specimens or for the using S-clips. Six mounting clips M2 included.

£0.00Price On Request