Welcome to our new site, if you can’t find what you’re looking for please get in touch via our contact us page.

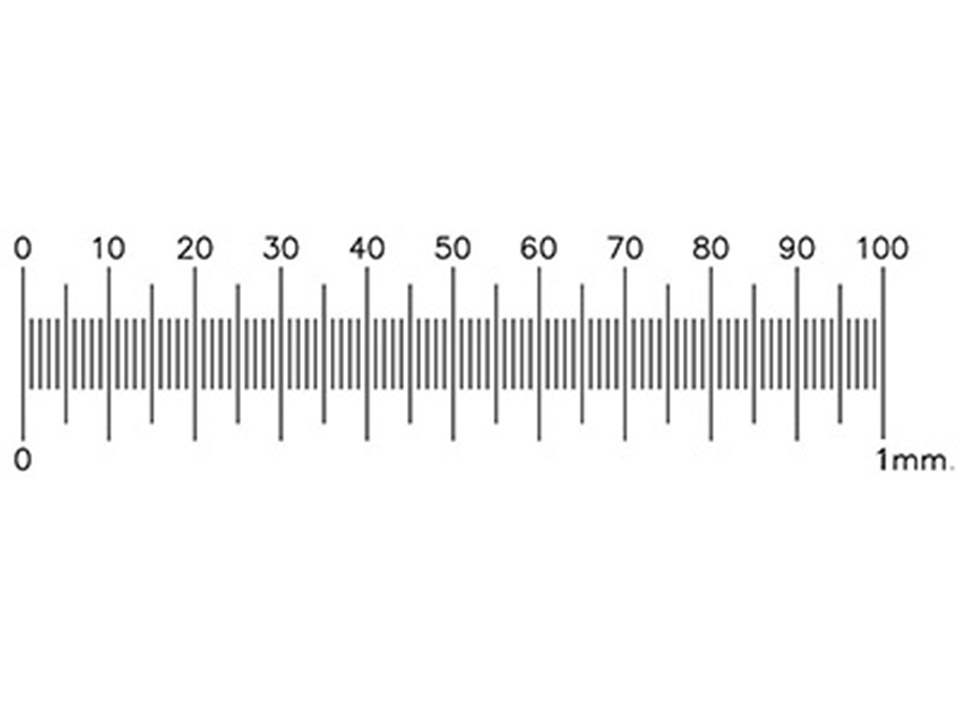

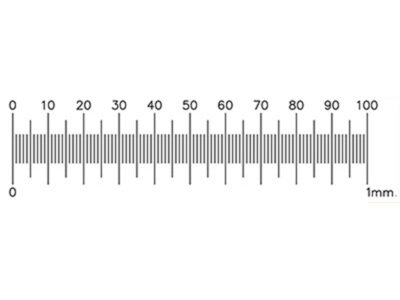

S48 Micrometer scale without coverglass no certificate

S48 Micrometer scale 1mm/0.01mm divisions without coverglass. Mounted in a black anodised aluminium slide (each).

£115.17

Related products

-

S22 Micrometer scale 2mm in 0.01mm divisions no certificate

S22 Micrometer scale 2mm in 0.01mm divisions, mounted in a black anodised aluminium slide (each).

SKU: 02A00411£115.17 Add to basketAdd to QuoteWithin your QuoteAdd to QuoteS22 Micrometer scale 2mm in 0.01mm divisions no certificate

S22 Micrometer scale 2mm in 0.01mm divisions, mounted in a black anodised aluminium slide (each).

£115.17 -

S8 micrometer scale 1mm in 0.01mm divisions no certificate

S8 Micrometer scale 1mm in 0.01mm divisions, mounted in a black anodised aluminium slide (each).

SKU: 02A00404£101.14 Add to basketAdd to QuoteWithin your QuoteAdd to QuoteS8 micrometer scale 1mm in 0.01mm divisions no certificate

S8 Micrometer scale 1mm in 0.01mm divisions, mounted in a black anodised aluminium slide (each).

£101.14 -

S78 Micrometer scale (for reflected light) no certificate

S78 Micrometer scale with 1mm scale in 0.01mm divisions for reflected light. The scale is etched in a highly reflective chromium layer for reflected light and appears black against a white background. Mounted in a black anodised aluminium slide (each).

SKU: 02B00421£115.17 Add to basketAdd to QuoteWithin your QuoteAdd to QuoteS78 Micrometer scale (for reflected light) no certificate

S78 Micrometer scale with 1mm scale in 0.01mm divisions for reflected light. The scale is etched in a highly reflective chromium layer for reflected light and appears black against a white background. Mounted in a black anodised aluminium slide (each).

£115.17 -

SP-010 sputtering module

Fully integrated magnetron (type A) sputtering module for standard sputtering rates. Including high resolution sputtering assembly. Fitted with target cooling and monitoring – automatic source shutter and electronically controlled process vacuum control. Note: sputtering target not included – please select required metat target(s) from the options list.

SKU: 100002Price On Request £0.00 Add to basketAdd to QuoteWithin your QuoteAdd to QuoteSP-010 sputtering module

Fully integrated magnetron (type A) sputtering module for standard sputtering rates. Including high resolution sputtering assembly. Fitted with target cooling and monitoring – automatic source shutter and electronically controlled process vacuum control. Note: sputtering target not included – please select required metat target(s) from the options list.

£0.00Price On Request