Welcome to our new site, if you can’t find what you’re looking for please get in touch via our contact us page.

Micro-Tec wafer carrier tray 4 inch or 100mm diameter

Micro-Tec wafer carrier tray 4 inch or 100mm diameter (pkg/5)

£47.44

Related products

-

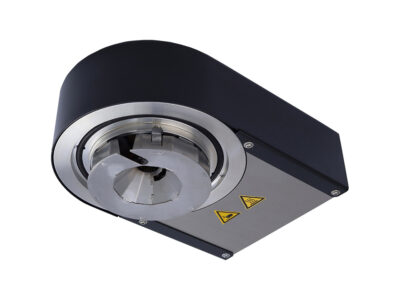

CT-010 carbon coating module

Carbon fibre thread evaporation module with unique thread tracking system, allowing up to 50 coatings without having to break vacuum and replenish the carbon source. Controlled, automatic pulse evaporation modes give optimal coating control and film quality. Easy-fit electrical and pneumatic interface to CCU-010 LV and CCU-010 HV platforms. Includes one 300015 carbon thread on coil 2m.

SKU: 100003Price On Request £0.00 Add to basketAdd to QuoteWithin your QuoteAdd to QuoteCT-010 carbon coating module

Carbon fibre thread evaporation module with unique thread tracking system, allowing up to 50 coatings without having to break vacuum and replenish the carbon source. Controlled, automatic pulse evaporation modes give optimal coating control and film quality. Easy-fit electrical and pneumatic interface to CCU-010 LV and CCU-010 HV platforms. Includes one 300015 carbon thread on coil 2m.

£0.00Price On Request -

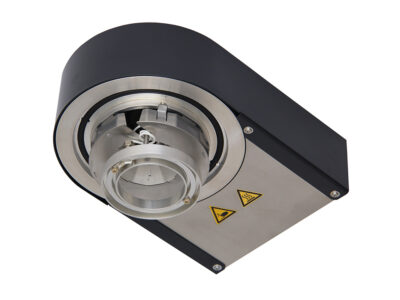

GD-010 glow discharge

Glow discharge attachment for hydrophilic/hydrophobic treatment (rendering) of substrates (e.g. TEM carbon support films). Fully integrated to allow post-treatment of carbon films without the need to break vacuum after carbon coating

SKU: 100004Price On Request £0.00 Add to basketAdd to QuoteWithin your QuoteAdd to QuoteGD-010 glow discharge

Glow discharge attachment for hydrophilic/hydrophobic treatment (rendering) of substrates (e.g. TEM carbon support films). Fully integrated to allow post-treatment of carbon films without the need to break vacuum after carbon coating

£0.00Price On Request -

Carrier tray 4 inch/100mmØ, anti-static black Polypropylene

Micro-Tec carrier tray 4 inch/100mm diameter, anti-static black Polypropylene (pkg/5)

SKU: 10-008184£57.40 Add to basketAdd to QuoteWithin your QuoteAdd to QuoteCarrier tray 4 inch/100mmØ, anti-static black Polypropylene

Micro-Tec carrier tray 4 inch/100mm diameter, anti-static black Polypropylene (pkg/5)

£57.40 -

Micro-Tec wafer carrier tray 3 inch or 100mm diameter

Micro-Tec wafer carrier tray 3 inch or 76mm diameter (pkg/5)

SKU: 10-008193£44.32 Add to basketAdd to QuoteWithin your QuoteAdd to QuoteMicro-Tec wafer carrier tray 3 inch or 100mm diameter

Micro-Tec wafer carrier tray 3 inch or 76mm diameter (pkg/5)

£44.32