Welcome to our new site, if you can’t find what you’re looking for please get in touch via our contact us page.

Hitachi Ø25 x 16mm M4 angled SEM stub – 45 and 90 degree

Hitachi Ø25 x 16mm M4 angled SEM sample stub, 45 and 90 degree – aluminium (pkg/1)

£5.19

Related products

-

Edwards RV3 rotary vacuum pump (including Ultragrade oil) with 2m UK mains lead

Edwards RV3 Two stage rotary vaccum pump 115/230V- 1-ph- 50/60Hz. Factory set to 230V for Europe• Speed (Pneurop 6602) 50 Hz: 3.3 m3h1 / 2 ft3min1 60Hz: 3.9 m3h1/ 2.3 ft3min1• Ultimate pressure 2.0 x 103mbar / 1.5 x 103 Torr• Inlet flange: NW25 / exhaust flange: NW25• Supplied with: 1 litre of Ultragrade 19 oil-inlet filter and O-ring• EMF10 (A46226000) exhaust oil mist filter recommended • Includes – A50505000UK/Ireland 2m mains lead

SKU: A65201903Price On Request £0.00 Add to basketAdd to QuoteWithin your QuoteAdd to QuoteEdwards RV3 rotary vacuum pump (including Ultragrade oil) with 2m UK mains lead

Edwards RV3 Two stage rotary vaccum pump 115/230V- 1-ph- 50/60Hz. Factory set to 230V for Europe• Speed (Pneurop 6602) 50 Hz: 3.3 m3h1 / 2 ft3min1 60Hz: 3.9 m3h1/ 2.3 ft3min1• Ultimate pressure 2.0 x 103mbar / 1.5 x 103 Torr• Inlet flange: NW25 / exhaust flange: NW25• Supplied with: 1 litre of Ultragrade 19 oil-inlet filter and O-ring• EMF10 (A46226000) exhaust oil mist filter recommended • Includes – A50505000UK/Ireland 2m mains lead

£0.00Price On Request -

RS-010 rotary table

Plug-in style rotary specimen table with smooth adjustment of table height, tilt angle and rotational speed. The 80mm diameter stage has locations for up to 20 standard (13 mm) SEM pin stubs or five 25mm stubs. On request other sizes and styles of SEM stubs can be accommodated.

SKU: 100005Price On Request £0.00 Add to basketAdd to QuoteWithin your QuoteAdd to QuoteRS-010 rotary table

Plug-in style rotary specimen table with smooth adjustment of table height, tilt angle and rotational speed. The 80mm diameter stage has locations for up to 20 standard (13 mm) SEM pin stubs or five 25mm stubs. On request other sizes and styles of SEM stubs can be accommodated.

£0.00Price On Request -

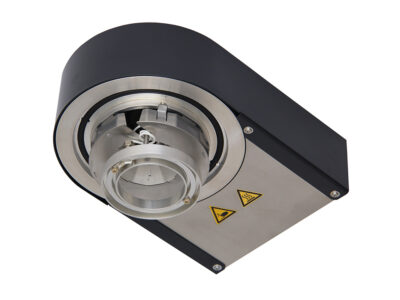

GD-010 glow discharge

Glow discharge attachment for hydrophilic/hydrophobic treatment (rendering) of substrates (e.g. TEM carbon support films). Fully integrated to allow post-treatment of carbon films without the need to break vacuum after carbon coating

SKU: 100004Price On Request £0.00 Add to basketAdd to QuoteWithin your QuoteAdd to QuoteGD-010 glow discharge

Glow discharge attachment for hydrophilic/hydrophobic treatment (rendering) of substrates (e.g. TEM carbon support films). Fully integrated to allow post-treatment of carbon films without the need to break vacuum after carbon coating

£0.00Price On Request -

RC-010 software for remote control of CCU-010

Windows-based RC-010 remote control software allows Safematic CCU-010 coaters to be run remotely for the control, monitoring and analysis of coating processes, for example in a glove box. The RC-010 comes ready with pre-defined recipes with optimal settings for the most common metal sputtering targets as well as for carbon. Requires connection from a laptop or computer (not supplied) to the CCU-010 coating system via a USB cable.

SKU: 1000202Price On Request £0.00 Add to basketAdd to QuoteWithin your QuoteAdd to QuoteRC-010 software for remote control of CCU-010

Windows-based RC-010 remote control software allows Safematic CCU-010 coaters to be run remotely for the control, monitoring and analysis of coating processes, for example in a glove box. The RC-010 comes ready with pre-defined recipes with optimal settings for the most common metal sputtering targets as well as for carbon. Requires connection from a laptop or computer (not supplied) to the CCU-010 coating system via a USB cable.

£0.00Price On Request