Welcome to our new site, if you can’t find what you’re looking for please get in touch via our contact us page.

H71 EBSD 70° pre-tilt sample holder for Ø25mm mounts – M4

EM-Tec H71 EBSD 70° pre-tilt sample holder for Ø25mm / Ø1inch mounts – M4 (each)

£93.17

Related products

-

RS-010 rotary table

Plug-in style rotary specimen table with smooth adjustment of table height, tilt angle and rotational speed. The 80mm diameter stage has locations for up to 20 standard (13 mm) SEM pin stubs or five 25mm stubs. On request other sizes and styles of SEM stubs can be accommodated.

SKU: 100005Price On Request £0.00 Add to basketAdd to QuoteWithin your QuoteAdd to QuoteRS-010 rotary table

Plug-in style rotary specimen table with smooth adjustment of table height, tilt angle and rotational speed. The 80mm diameter stage has locations for up to 20 standard (13 mm) SEM pin stubs or five 25mm stubs. On request other sizes and styles of SEM stubs can be accommodated.

£0.00Price On Request -

Carbon fibre thread on coil – 2m

High purity carbon fibre thread on coil, 2 metre.

SKU: 300015Price On Request £0.00 Add to basketAdd to QuoteWithin your QuoteAdd to Quote£0.00Price On Request -

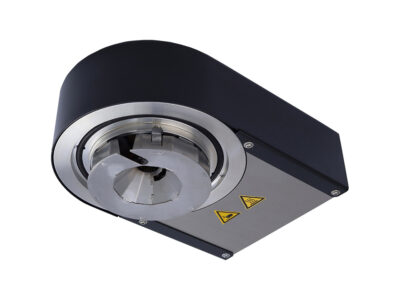

CT-010 carbon coating module

Carbon fibre thread evaporation module with unique thread tracking system, allowing up to 50 coatings without having to break vacuum and replenish the carbon source. Controlled, automatic pulse evaporation modes give optimal coating control and film quality. Easy-fit electrical and pneumatic interface to CCU-010 LV and CCU-010 HV platforms. Includes one 300015 carbon thread on coil 2m.

SKU: 100003Price On Request £0.00 Add to basketAdd to QuoteWithin your QuoteAdd to QuoteCT-010 carbon coating module

Carbon fibre thread evaporation module with unique thread tracking system, allowing up to 50 coatings without having to break vacuum and replenish the carbon source. Controlled, automatic pulse evaporation modes give optimal coating control and film quality. Easy-fit electrical and pneumatic interface to CCU-010 LV and CCU-010 HV platforms. Includes one 300015 carbon thread on coil 2m.

£0.00Price On Request -

NW25 braided flexible pipeline stainless steel 1000mm

Flexible metal vacuum hose with connecting clamps, O-rings and O-ring carriers

SKU: C10514297£225.87 Add to basketAdd to QuoteWithin your QuoteAdd to QuoteNW25 braided flexible pipeline stainless steel 1000mm

Flexible metal vacuum hose with connecting clamps, O-rings and O-ring carriers

£225.87