Welcome to our new site, if you can’t find what you’re looking for please get in touch via our contact us page.

FEI F20 short brass SEM stage adaptor pillar only – 20mm x M6F

FEI F20 short brass SEM stage adaptor pillar only, 20mm x M6F (each)

£44.56

Related products

-

FEI F40 standard brass SEM stage adaptor pillar only

FEI F40 standard brass SEM stage adaptor pillar only, 40mm xM6F (each)

SKU: 11-000240£49.06 Add to basketAdd to QuoteWithin your QuoteAdd to QuoteFEI F40 standard brass SEM stage adaptor pillar only

FEI F40 standard brass SEM stage adaptor pillar only, 40mm xM6F (each)

£49.06 -

FEI F50 long brass SEM stage adaptor pillar only

FEI F50 long brass SEM stage adaptor pillar only – 50mm x M6F (each)

SKU: 11-000250£53.56 Add to basketAdd to QuoteWithin your QuoteAdd to QuoteFEI F50 long brass SEM stage adaptor pillar only

FEI F50 long brass SEM stage adaptor pillar only – 50mm x M6F (each)

£53.56 -

SEM stage adaptor pillar only- for FEI with M4 screw

EM-Tec standard brass SEM stage adaptor pillar only, for FEI with M4 screw – 40mm x M6F (each)

SKU: 11-000243£49.06 Add to basketAdd to QuoteWithin your QuoteAdd to QuoteSEM stage adaptor pillar only- for FEI with M4 screw

EM-Tec standard brass SEM stage adaptor pillar only, for FEI with M4 screw – 40mm x M6F (each)

£49.06 -

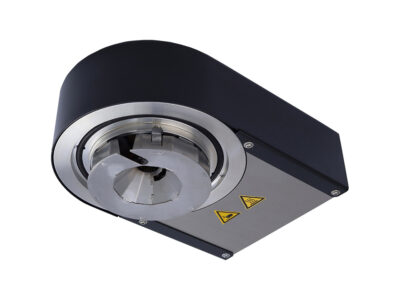

CT-010 carbon coating module

Carbon fibre thread evaporation module with unique thread tracking system, allowing up to 50 coatings without having to break vacuum and replenish the carbon source. Controlled, automatic pulse evaporation modes give optimal coating control and film quality. Easy-fit electrical and pneumatic interface to CCU-010 LV and CCU-010 HV platforms. Includes one 300015 carbon thread on coil 2m.

SKU: 100003Price On Request £0.00 Add to basketAdd to QuoteWithin your QuoteAdd to QuoteCT-010 carbon coating module

Carbon fibre thread evaporation module with unique thread tracking system, allowing up to 50 coatings without having to break vacuum and replenish the carbon source. Controlled, automatic pulse evaporation modes give optimal coating control and film quality. Easy-fit electrical and pneumatic interface to CCU-010 LV and CCU-010 HV platforms. Includes one 300015 carbon thread on coil 2m.

£0.00Price On Request