Welcome to our new site, if you can’t find what you’re looking for please get in touch via our contact us page.

EM-Tec high purity carbon Hitachi SEM sample stub – Ø15 x 6mm x M4

EM-Tec high purity carbon Hitachi SEM sample stub – Ø15 x 6mm x M4 (each)

£2.84

Related products

-

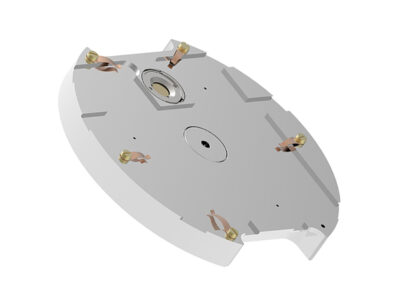

PS-006 planetary gear table

Consisting of base plate for connection to the tilt and height adjustable specimen table of the CCU-010 base unit. Specimen holders for six large (Ø 25.4mm) or six small (Ø12.7mm) SEM pin stubs. DC micro-motor for rotation and planetary movement, quartz sensor (centre), speed control: 0-100%, rotation: 0-20rpm approximately, planets: 0-65rpm approximately

SKU: 1000130Price On Request £0.00 Add to basketAdd to QuoteWithin your QuoteAdd to QuotePS-006 planetary gear table

Consisting of base plate for connection to the tilt and height adjustable specimen table of the CCU-010 base unit. Specimen holders for six large (Ø 25.4mm) or six small (Ø12.7mm) SEM pin stubs. DC micro-motor for rotation and planetary movement, quartz sensor (centre), speed control: 0-100%, rotation: 0-20rpm approximately, planets: 0-65rpm approximately

£0.00Price On Request -

RS-010 rotary table

Plug-in style rotary specimen table with smooth adjustment of table height, tilt angle and rotational speed. The 80mm diameter stage has locations for up to 20 standard (13 mm) SEM pin stubs or five 25mm stubs. On request other sizes and styles of SEM stubs can be accommodated.

SKU: 100005Price On Request £0.00 Add to basketAdd to QuoteWithin your QuoteAdd to QuoteRS-010 rotary table

Plug-in style rotary specimen table with smooth adjustment of table height, tilt angle and rotational speed. The 80mm diameter stage has locations for up to 20 standard (13 mm) SEM pin stubs or five 25mm stubs. On request other sizes and styles of SEM stubs can be accommodated.

£0.00Price On Request -

ST-010 object slide table

ST-010 specimen stage for microscopy slides. Comprises base plate connected to the tilt and height adjustable specimen table of the CCU-010 base unit. For two microscopy slides 76 x 26mm or one slide 76 x 52mm. Can also be used for coverslips. Twelve M2 threaded holes for S-clips. Two FTM quartz crystal positions (centre and edge). Six mounting clips M2 included.

SKU: 1000088Price On Request £0.00 Add to basketAdd to QuoteWithin your QuoteAdd to QuoteST-010 object slide table

ST-010 specimen stage for microscopy slides. Comprises base plate connected to the tilt and height adjustable specimen table of the CCU-010 base unit. For two microscopy slides 76 x 26mm or one slide 76 x 52mm. Can also be used for coverslips. Twelve M2 threaded holes for S-clips. Two FTM quartz crystal positions (centre and edge). Six mounting clips M2 included.

£0.00Price On Request -

EM-Tec high purity carbon SEM pin stub Ø12.7mm top x 8mm L – standard pin

EM-Tec high purity carbon SEM pin stub Ø12.7mm top x 8mm L – standard pin (each)

SKU: 10-CC2012-1£1.93 Add to basketAdd to QuoteWithin your QuoteAdd to QuoteEM-Tec high purity carbon SEM pin stub Ø12.7mm top x 8mm L – standard pin

EM-Tec high purity carbon SEM pin stub Ø12.7mm top x 8mm L – standard pin (each)

£1.93