Welcome to our new site, if you can’t find what you’re looking for please get in touch via our contact us page.

50.08mm/2″ large capacity specimen holder

50.08mm/2″ large capacity specimen holder

£0.00

Related products

-

Rotary support for PS-006

Rotary support for use with the PS-006 planetary gear stage. Includes slip-on specimen holder which converts the planetary gear stage into a rotary stage. Twelve M2 threads for mounting specimens or for the using S-clips. Six mounting clips M2 included.

SKU: 1000089Price On Request £0.00 Add to basketAdd to QuoteWithin your QuoteAdd to QuoteRotary support for PS-006

Rotary support for use with the PS-006 planetary gear stage. Includes slip-on specimen holder which converts the planetary gear stage into a rotary stage. Twelve M2 threads for mounting specimens or for the using S-clips. Six mounting clips M2 included.

£0.00Price On Request -

High vacuum (HV) upgrade kit I

Upgrade kit for converting CCU-010 LV to high vacuum CCU-010 HV specification. Includes turbomolecular pump (Pfeiffer Hi Pace 80), conversion kit, cable and other small components. Note: the rotary vacuum pump used with the LV version will be required to “back” the internally mounted turbomolecular pump.

SKU: 200000Price On Request £0.00 Add to basketAdd to QuoteWithin your QuoteAdd to QuoteHigh vacuum (HV) upgrade kit I

Upgrade kit for converting CCU-010 LV to high vacuum CCU-010 HV specification. Includes turbomolecular pump (Pfeiffer Hi Pace 80), conversion kit, cable and other small components. Note: the rotary vacuum pump used with the LV version will be required to “back” the internally mounted turbomolecular pump.

£0.00Price On Request -

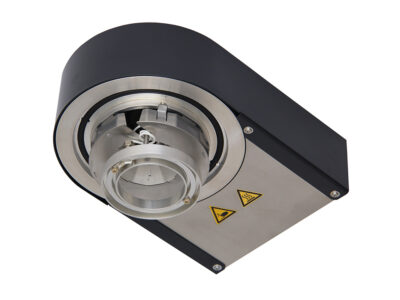

GD-010 glow discharge

Glow discharge attachment for hydrophilic/hydrophobic treatment (rendering) of substrates (e.g. TEM carbon support films). Fully integrated to allow post-treatment of carbon films without the need to break vacuum after carbon coating

SKU: 100004Price On Request £0.00 Add to basketAdd to QuoteWithin your QuoteAdd to QuoteGD-010 glow discharge

Glow discharge attachment for hydrophilic/hydrophobic treatment (rendering) of substrates (e.g. TEM carbon support films). Fully integrated to allow post-treatment of carbon films without the need to break vacuum after carbon coating

£0.00Price On Request -

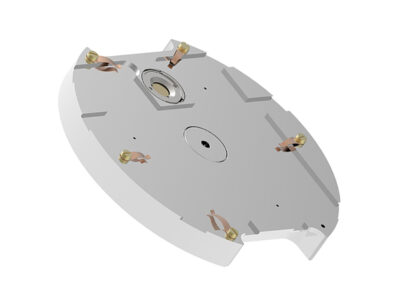

ST-010 object slide table

ST-010 specimen stage for microscopy slides. Comprises base plate connected to the tilt and height adjustable specimen table of the CCU-010 base unit. For two microscopy slides 76 x 26mm or one slide 76 x 52mm. Can also be used for coverslips. Twelve M2 threaded holes for S-clips. Two FTM quartz crystal positions (centre and edge). Six mounting clips M2 included.

SKU: 1000088Price On Request £0.00 Add to basketAdd to QuoteWithin your QuoteAdd to QuoteST-010 object slide table

ST-010 specimen stage for microscopy slides. Comprises base plate connected to the tilt and height adjustable specimen table of the CCU-010 base unit. For two microscopy slides 76 x 26mm or one slide 76 x 52mm. Can also be used for coverslips. Twelve M2 threaded holes for S-clips. Two FTM quartz crystal positions (centre and edge). Six mounting clips M2 included.

£0.00Price On Request