Welcome to our new site, if you can’t find what you’re looking for please get in touch via our contact us page.

Welcome to our new site, if you can’t find what you’re looking for please get in touch via our contact us page.

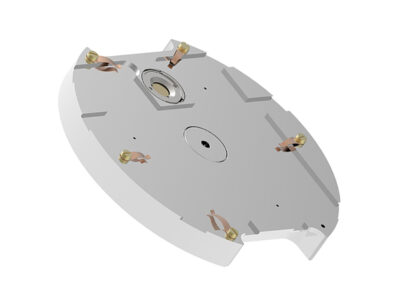

ST-010 specimen stage for microscopy slides. Comprises base plate connected to the tilt and height adjustable specimen table of the CCU-010 base unit. For two microscopy slides 76 x 26mm or one slide 76 x 52mm. Can also be used for coverslips. Twelve M2 threaded holes for S-clips. Two FTM quartz crystal positions (centre and edge). Six mounting clips M2 included.

ST-010 specimen stage for microscopy slides. Comprises base plate connected to the tilt and height adjustable specimen table of the CCU-010 base unit. For two microscopy slides 76 x 26mm or one slide 76 x 52mm. Can also be used for coverslips. Twelve M2 threaded holes for S-clips. Two FTM quartz crystal positions (centre and edge). Six mounting clips M2 included.

Windows-based RC-010 remote control software allows Safematic CCU-010 coaters to be run remotely for the control, monitoring and analysis of coating processes, for example in a glove box. The RC-010 comes ready with pre-defined recipes with optimal settings for the most common metal sputtering targets as well as for carbon. Requires connection from a laptop or computer (not supplied) to the CCU-010 coating system via a USB cable.

Windows-based RC-010 remote control software allows Safematic CCU-010 coaters to be run remotely for the control, monitoring and analysis of coating processes, for example in a glove box. The RC-010 comes ready with pre-defined recipes with optimal settings for the most common metal sputtering targets as well as for carbon. Requires connection from a laptop or computer (not supplied) to the CCU-010 coating system via a USB cable.

Coating LAB Windows-based software can be installed on a laptop for monitoring and documenting coating processes. Fully automatic logs and charts containing all process-related data can be exported as screenshots or CSV files for Office applications. Available information includes process vacuum, current and voltage along with film thickness and coating rates (Internet connection required). Coating-LAB will allow remote service access for error diagnosis and process optimisation.

Coating LAB Windows-based software can be installed on a laptop for monitoring and documenting coating processes. Fully automatic logs and charts containing all process-related data can be exported as screenshots or CSV files for Office applications. Available information includes process vacuum, current and voltage along with film thickness and coating rates (Internet connection required). Coating-LAB will allow remote service access for error diagnosis and process optimisation.

nXDS6i Scroll Pump.Peak pumping speed: 6m3/hr (3.53 cfm).Utimate pressure: 0.02mbar (1.5e-2 torr).Inverter drive with push button control – remote serial and parallel.control and USB interface.Supply: 100-127/200-240V 1ph 50/60Hz without user intervention.Inlet port: NW25. Exhaust port: NW25.

nXDS6i Scroll Pump.Peak pumping speed: 6m3/hr (3.53 cfm).Utimate pressure: 0.02mbar (1.5e-2 torr).Inverter drive with push button control – remote serial and parallel.control and USB interface.Supply: 100-127/200-240V 1ph 50/60Hz without user intervention.Inlet port: NW25. Exhaust port: NW25.